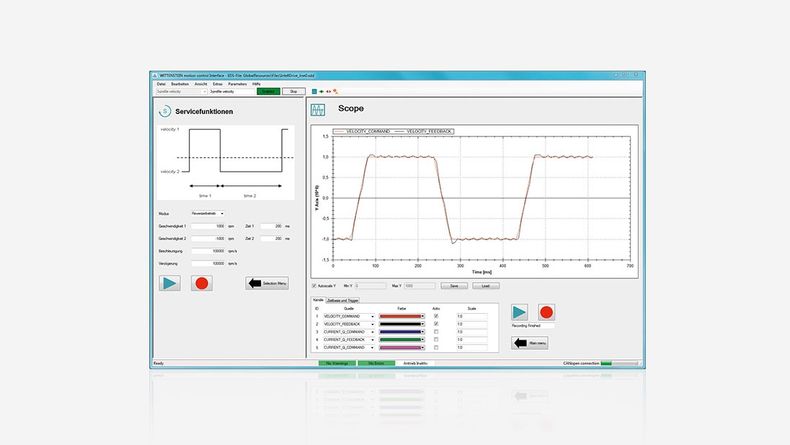

Small servo drive system

A perfect match: Two top performers – an ideal pair

The cyber® dynamic line and simco® drive make the perfect couple: an all-in-one motor and servo drive, fast commissioning, single-cable solution, maximum power. Additionally cyber® dynamic line is as an motor-gearbox-combination available. Both systems are based on the same development philosophy: incorporate safety, smart technology (functionality) and resource efficiency at an early stage, while also implementing the technology trends of miniaturization, integration and network capability.

![]() For a reduced project planning workload in your electrical design, the products are now available in EPLAN.

For a reduced project planning workload in your electrical design, the products are now available in EPLAN.

With Small servo drive system we are a worldwide partner in the Encompass program of Rockwell Automation.

Downloads

- Flyer cyber® dynamic line (2 MB)

- Flyer small servo drive system (3 MB)

- Flyer small servo drive system (Generation 2) (2 MB)

- Catalog small servo drive system (Generation 2) (13 MB)

- Technical data (CAD/CAE, dimension sheet, data sheet)

- Technical data (CAD/CAE, dimension sheet, data sheet)

- Technical data (CAD/CAE, dimension sheet, data sheet)

WITTENSTEIN cyber motor

Walter-Wittenstein-Straße 1

97999 Igersheim