We make AGVs flatter

An ultra-flat automated guided vehicle (AGV) system developed by 2-IT GmbH can also drive underneath the load. The new system is based on WITTENSTEIN's traction drive system (TDS).

AGVs get things moving in intralogistics

AGV systems are used by companies to move goods and materials from A to B. They appear to be able to find their own way: they avoid obstacles and can move forwards, backwards and even sideways. The total weight of each vehicle is between around 300 kilograms and 25 tons. These innovative AGVs are moved by electric drives.

Treading new paths with flat AGVs

2-IT – innovative solutions for AGVs

2-IT GmbH of Alling, just outside Munich, has two business divisions: one is devoted to IT while the other specializes in the development, installation and commissioning of AGVs. The company designs its innovative solutions with the help of external software and IT experts as well as designers and electrical engineers, who are organized in a 50-strong network. Interdisciplinary, project oriented teams ensure that both technology and commercial aspects are optimally efficient.

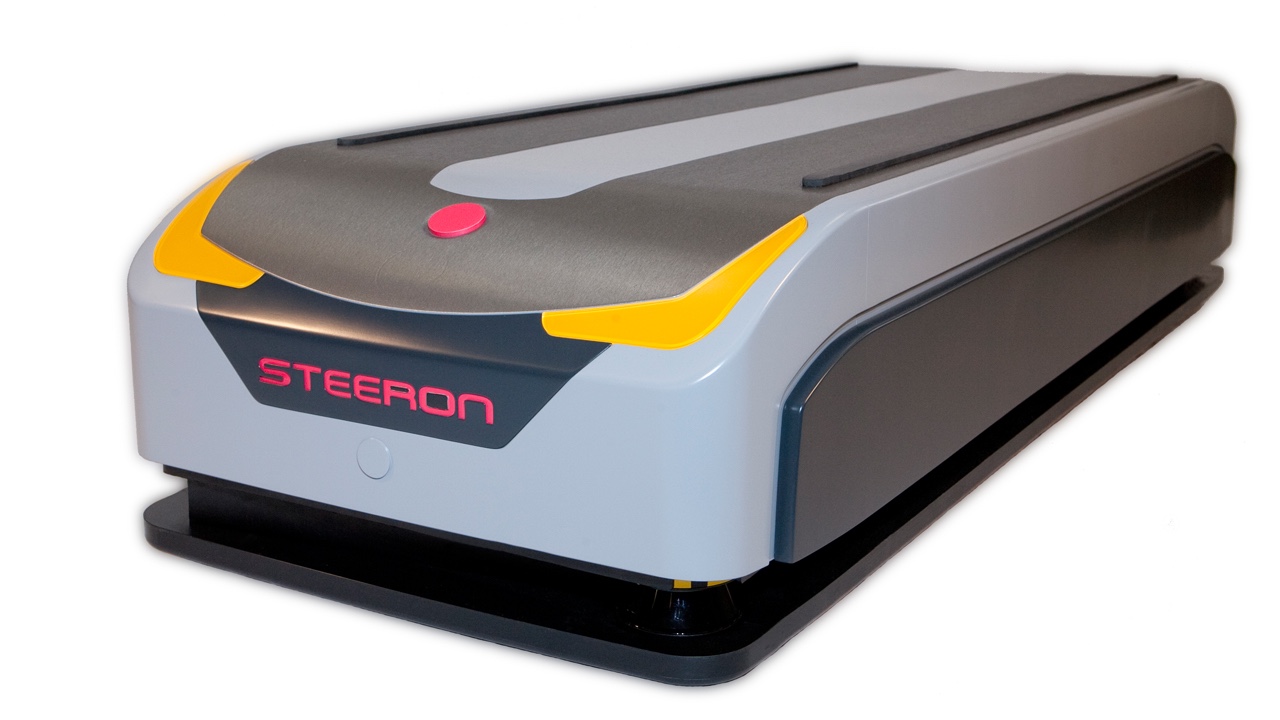

STEERON – pioneering transport applications for the healthcare sector

An AGV developed by 2-IT in the framework of the STEERON project is capable of driving underneath the load, making it ideal for numerous transport applications in healthcare facilities. The vehicles navigate around the contours of buildings and master upward or downward gradients as well as elevator entrances, following the same routes as the facility's staff One special feature of hospitals or nursing homes is that the vehicles used there generally have to drive underneath the load such as a food or laundry container in order to pick it up. The AGV therefore needs to be as flat as possible – and the components integrated in it must support this type of construction.

The new vehicle is approximately 1.7 meters long, 60 centimeters wide – and just 33 centimeters high. Thanks to the integral scissor lift table, loads weighing up to 600 kilograms can be handled without any problems. Miniature laser scanners, ultrasonic sensors and floor detectors guarantee safe navigation. The vehicle's TDS concept is also unique: the drive unit is extremely flat with a very high power density. As a result, the AGV can travel at a rate of up to 2 meters per second and overcome 7 percent gradients. Since the TDS is structured as a differential drive, the vehicle can be steered according to the speed difference between the two drives – and if necessary, it will even turn on its own axis. The drives' 93 percent energy efficiency is equally remarkable, contributing significantly to the high availability of the vehicles. Driving cycles of 20 hours or more are not uncommon.

TDS creates new opportunities

Thanks to its high power density, low power consumption and plug & play design, our traction drive system is the ideal solution for motion tasks in AGVs. The servo actuators of the TDS unite a motor and a helical-toothed, low-backlash planetary gearbox in a coupling-free drive unit distinguished by high dynamics, high torque and enormous tilting and torsional rigidity. The servo drives impress with high-resolution current control and high torque precision.

The gearboxes for the TDS are integrated directly in the VULKOLLAN® wheels. On the one hand, no valuable space is wasted in the warehouse while on the other, an exceptionally slim and compact design is possible – a clear advantage in applications where the load needs to be driven under. Since there are always two servo actuators per vehicle axis, each one only has to lift half the load, saving even more space.

This innovative AGV concept not only has benefits for hospital logistics: the compact, ultra-flat vehicles also tread new paths in industrial environments, where steel or paper coils have to be moved under in order to be lifted or shelves and racks taken to another location. The AGV can optionally be equipped with a roller conveyor instead of a scissor lift table for transporting heavy containers, for instance.

Top performer in four sizes

With the WITTENSTEIN traction drive system (TDS), manufacturers of AGVs now have access to the complete drive unit as an integration-friendly assembly. Each vehicle axle comprises two servo actuators belonging to the TPM+ family and decentralized servo amplifiers in the cyber® simco® drive series. Our TDS is offered in four different sizes covering a wide power range. The intelligent modular concept simultaneously allows extensive customizing, for example regarding the reduction ratio, the type of motor encoder and the bus interfaces. The configuration takes place in close cooperation with our team of experts. Our TDS also helped determine the optimal sizing of the complete drive solution in the STEERON project with 2-IT.