Oil & Gas Exploration

Brushless servo motors for downhole applications – proven in 20,000+ installations

WITTENSTEIN cyber motor delivers high-performance brushless DC servo motors engineered for the most demanding downhole environments. Designed for extreme conditions, our motors are trusted in over 20,000 installations across applications such as:

- Rotary Steerable Systems (RSS)

- Power Generation

- Pulser

- Measurement While Drilling (MWD)

- Logging While Drilling (LWD)

- Wireline Tools

- Downhole Tractors

- Coiled Tubing Systems

- Completion (e.g., Valve Actuators)

Strategic partner for China

Our components for downhole and topside applications

Explosion proof motors and actuators

Zone 1 & 2

Special features:

• IECEx certificated solutions with scalable torque and speed option

• Existing solutions as well as customized versions

• Voltage up to 560V

• Certified and tested for operating ambient temperatures up to 80°C

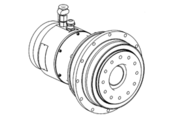

Brushless DC Motor with Hydraulic Pump Interface

(e.g. Rotary Steerable System)

Special features:

• >350 F & 30K PSI operating ambient conditions

• Proven shock & vibration resistant design

• Most reliable & durable high temperature/high pressure winding protection

• Interface for micro-hydraulic (e.g. Bieri)

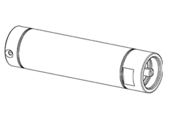

Frameless Brushless DC Motor

(e.g. Alternator, MWD, Wireline)

Special features:

• Rotor and Stator as kit

• Maximized compactness

• >350 F & 30K PSI operating ambient conditions

• Proven shock & vibration resistant design

• Most reliable & durable HT/HP 3-fold winding protection

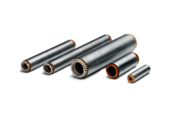

Small linear BLDC actuator (22mm & 30mm)

(e.g. Flow Control)

Special features:

• >350 F & 30K PSI operating ambient conditions

• Proven shock & vibration resistant design

• Most reliable & durable high temperature/high pressure winding protection

• Wide choice of feedback, gear, screw, front indexer options

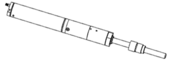

Small BLDC motor/actuator

(e.g. Wireline Applications)

Special features:

• >350 F & 30K PSI operating ambient conditions

• Proven shock & vibration resistant design

• Most reliable & durable HT/HP winding protection

• Wide choice of feedback & gear options

• Hollow Shaft Option

Zero-Speed Sensorless Control

Special features:

• No feedback device needed

• Full torque @ zero-speed

• Position control @ zero-speed

Maintenance & Service

• Customer-specific maintenance schedules

• Detailed documentation regarding condition and expected service life

• Regular maintenance of your drive through systematic replacement of wearing parts

• Proactive approach minimizes risk of failure and prevention of unplanned downtimes

Key features:

- Outer diameter: 22 – 76.2 mm (0.87 – 3 inches)

- Voltage range: 48 – 800 VDC

- Operating conditions: Up to 450 °F (232 °C) / 35,000 PSI (2,413 bar)

- Submersible in hydraulic oil

- Robustness: high shock & vibration resistance

With a proven portfolio and a team of experienced engineers, we ensure rapid customization and integration to meet your specific application requirements.