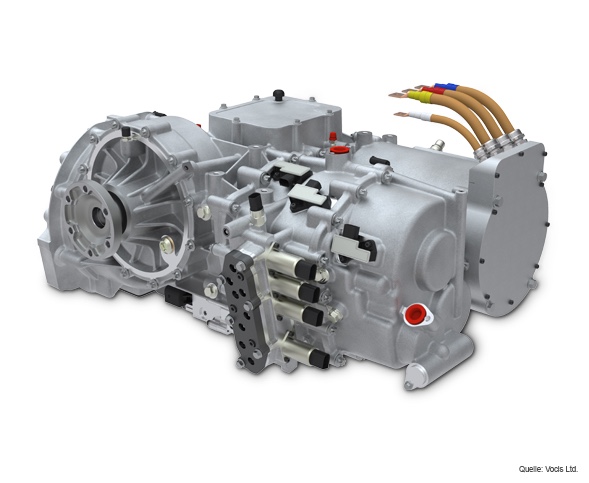

A prototype of the new gearbox has already been installed and developed in a Mercedes Benz SLS AMG by Vocis Ltd. The demonstration vehicle impressed OEM customers with the quality and speed of its gear changes. Oerlikon Graziano is a firm believer in this efficient, lightweight, compact and economical gearing solution for hybrid vehicles.

Gear changes with no torque interruption

Oerlikon Graziano and it's controlled UK company Vocis Ltd. have developed the high performance gearbox especially for hybrid vehicles, which compensates the torque interruption that occurs when changing gear with an automated manual transmission (AMT) system. A powerful and highly dynamic electric motor from WITTENSTEIN delivers the required torque during the shift process.

Convincingly simple – the alternative gearbox for hybrid vehicles.

Dual clutch transmission (DCT) systems provide a key benefit compared to automated manual transmissions (AMT): they facilitate gear changes with no torque interruption and hence very fast shift processes. The downside is a more complex mechanical design, higher weight and lower efficiency. The innovative, high performance gearbox created by Oerlikon Graziano's engineers finally offers a convincing alternative specifically for hybrid vehicles.

Pioneering gearbox for hybrid vehicles

Oerlikon Graziano – a leading specialist in drive train design

More than ninety years of experience underlie Oerlikon Graziano's position as a worldwide leader of complete drive systems and gearing solutions with Vocis Ltd. providing specialist driveline and control solutions. The product portfolio includes technology for sports cars as well as for off-highway and agricultural vehicles. From development and simulation to production, customers are guaranteed all steps from a single source. With know-how built up over several generations, acknowledged engineering excellence and innovative manufacturing, Oerlikon Graziano is today a leading supplier in the automotive and off-road sectors.

Our electric motor compensates the torque interruption

Oerlikon Graziano's revolutionary, high performance gearbox is a six-speed AMT with two additional speeds. The latter compensate the torque interruption by redirecting the motive power of WITTENSTEIN's electric motor to the wheels during the shift events – a function Oerlikon Graziano refers to as "torque infill". This same electric motor can also be used to start the internal combustion engine, and in addition to torque infill it performs all the tasks of a conventional, parallel hybrid drive train such as boosting, recuperation and all-electric driving, as implemented using novel software algorithms developed by Vocis Ltd.

No-one else delivers so much power from such a small footprint

Our solution came out clearly on top for Oerlikon Graziano – the electric motor from WITTENSTEIN was the only one capable of delivering the required power from such a small footprint. The active part has an outer diameter of 180 mm and is 150 mm long. The motor provides around 123 kW peak power at 320 V, outputs a torque of 190 Nm and can be operated at a speed of 14,000 rpm. Our novel electric motor is fully integrated in the Oerlikon Graziano gearbox housing.