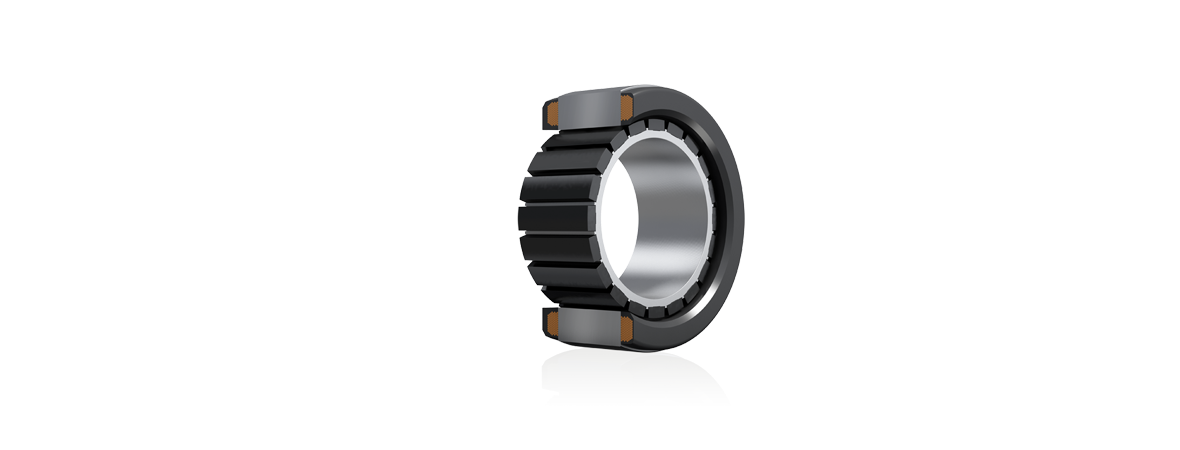

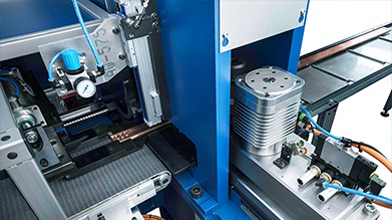

cyber® kit motor – frameless servo motors

compact – dynamic – highly integrable

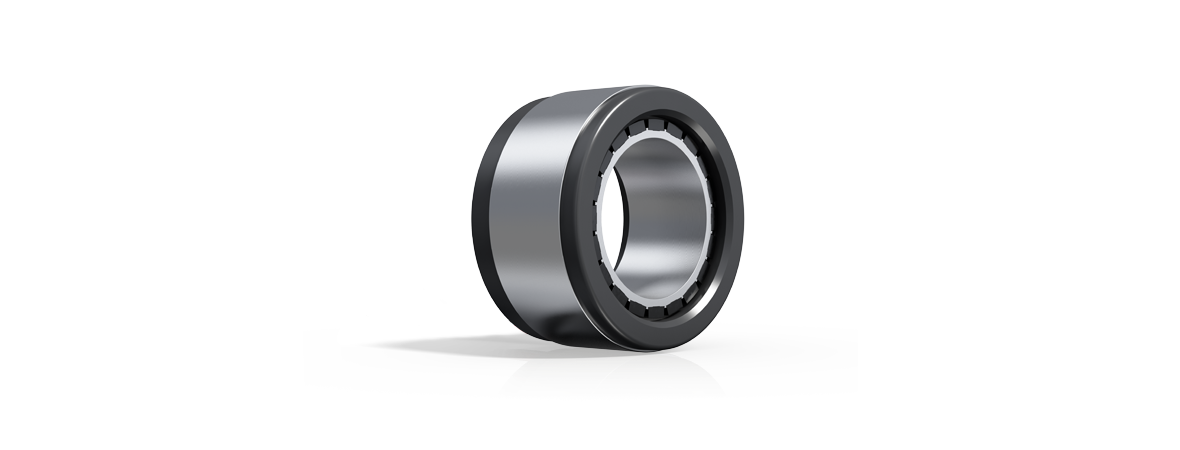

cyber® kit motors offer the ultimate performance and flexibility in a compact size. Stator and rotor kits give the design engineer the highest degree of integration freedom to develop unique solutions for application specific needs.

With cyber® kit motors we are a worldwide partner in the Encompass program of Rockwell Automation.

Downloads

- Brochure/Catalog (6 MB)

- Operating manual (828 KB)

WITTENSTEIN cyber motor

Walter-Wittenstein-Strasse 1

97999 Igersheim (Germany)

Webinar technical training:

How frameless servo motors are used

In this webinar, you will learn about the possible applications of our frameless servo motors from a technical perspective. You will learn what to consider when selecting, sizing, installing and operating these motors.

Your Benefits

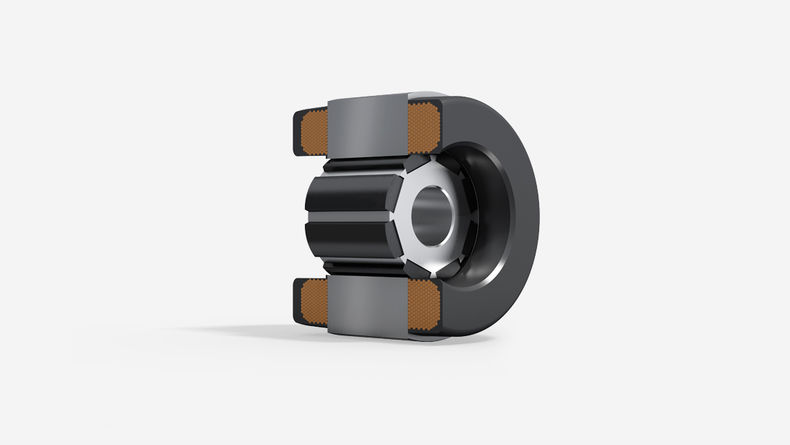

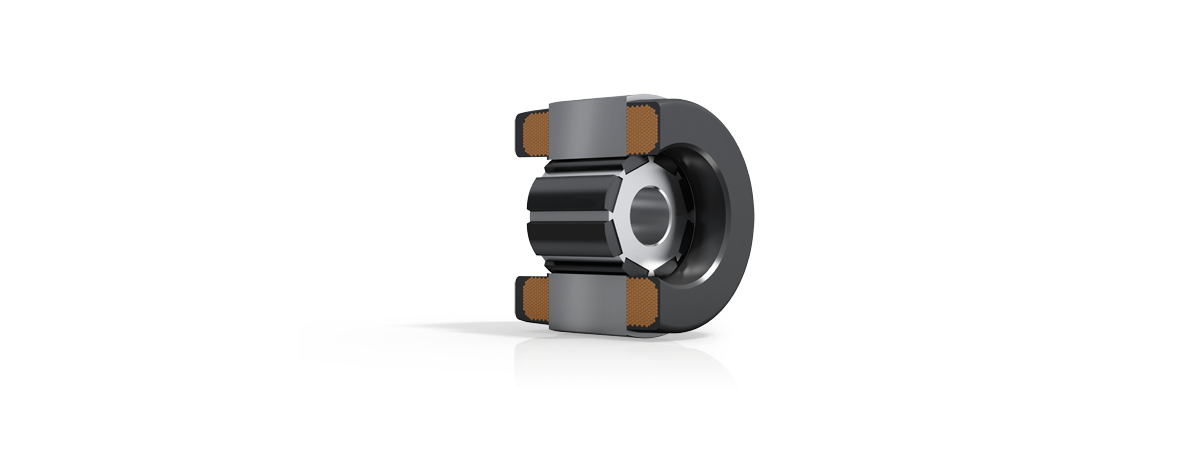

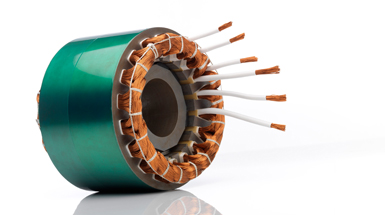

Compact design

- Maximum torque density

- Power density up to 10 kW/kg

- Low axial length due to minimized height of winding head

Efficiency

- Low power losses

- Low mass inertia

- Increased heat dissipation

Robustness

- Potted stators

- Test bench for frameless motors

- Extended and customized testing

Suitable for integration

- Support with integration (magnet retaining sleeve, insertion fixture)

- Customer-specific interfaces (mounting pattern, motor shaft, etc.)

- Expansion of the scope of delivery to provide a ready-to-install system

Precision

- Optimized synchronization characteristics

- Low torque ripple

- Minimal cogging torque

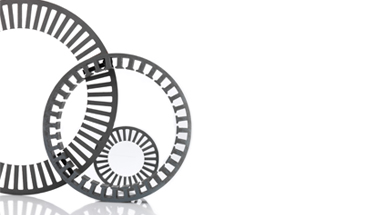

Flexibility

- Stator diameters from 19 mm to 440 mm

- Voltages up to 750 VDC possible

- Power & torque-optimized versions

Product range

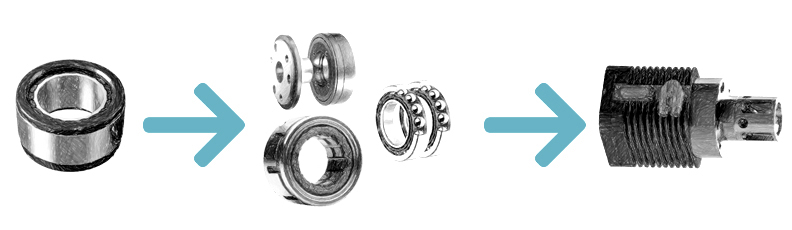

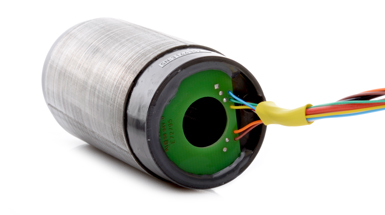

Integration in the overall system

We simplify and speed up integration in your application.

Maximum efficiency and superior performance data in a limited space are typical requirements for frameless motors. We can help you achieve ideal integration in your system. We can modify the interface and/or scope of delivery to ensure reliable and cost-effective installation.