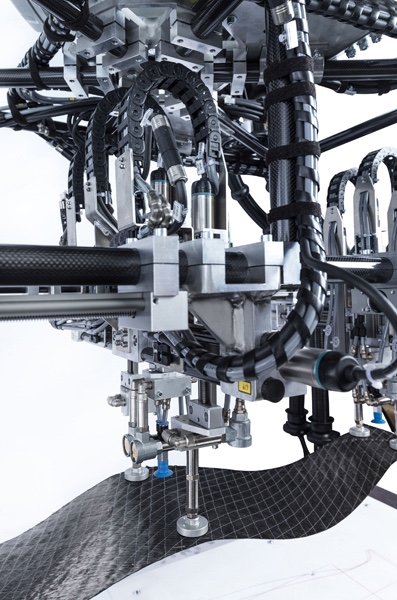

Highly precise motions during the production of CFRP and GFRP parts

Our servo drive technology enables flexible control of gripping elements

This new handling system from FILL, the Austrian mechanical engineering and plant construction company, is amazingly flexible: its motions can be executed steplessly and independently of one another. The gripper spider was equipped with intelligent small servo drive systems from WITTENSTEIN, which enable automated production of CFRP and GFRP parts on all axes.

Just take a look at this!

You can watch the innovative handling system in action here. Its precise, delicate motions are particularly impressive.

FILL-Website