cyber® dynamic actuator L with ball screw

dynamic – high torque – efficient

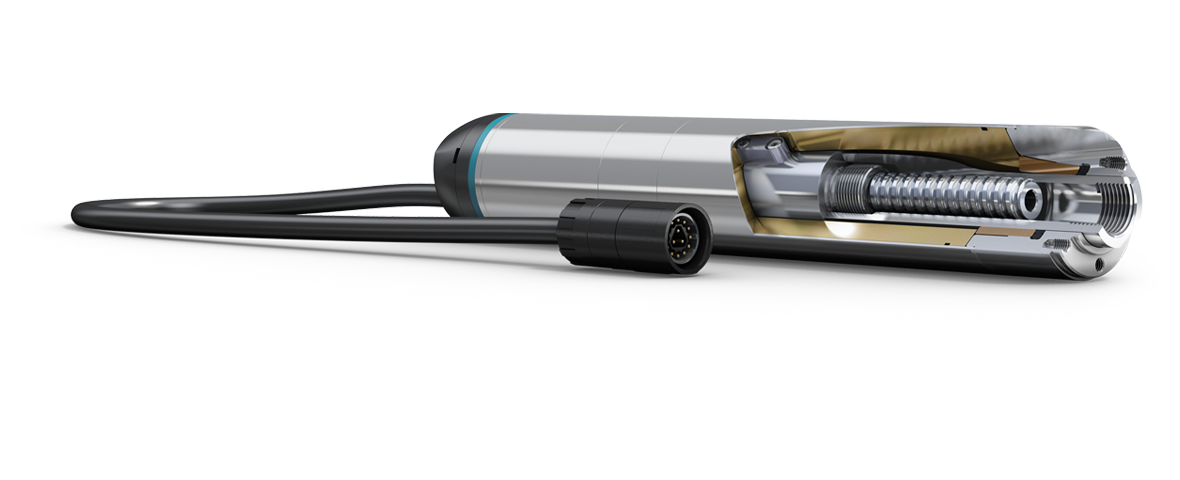

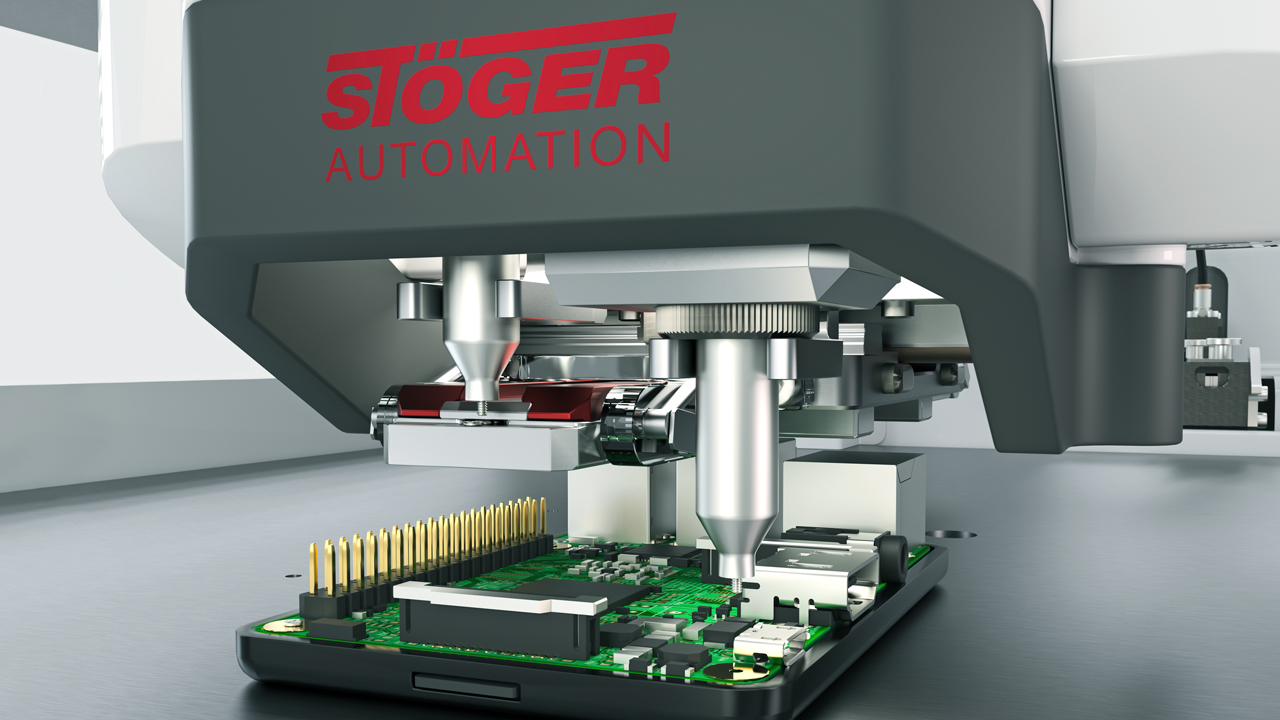

The industrial-grade linear actuators in the cyber® dynamic line are ideally suited for precise and flexible position control. As servo motors with an integrated ball screw, they represent an energy efficient and maintenance free alternative to pneumatic cylinders. The version with a closed pushing rod as well as a built-in linear guidance and anti-rotation mechanism forms a very compact unit.

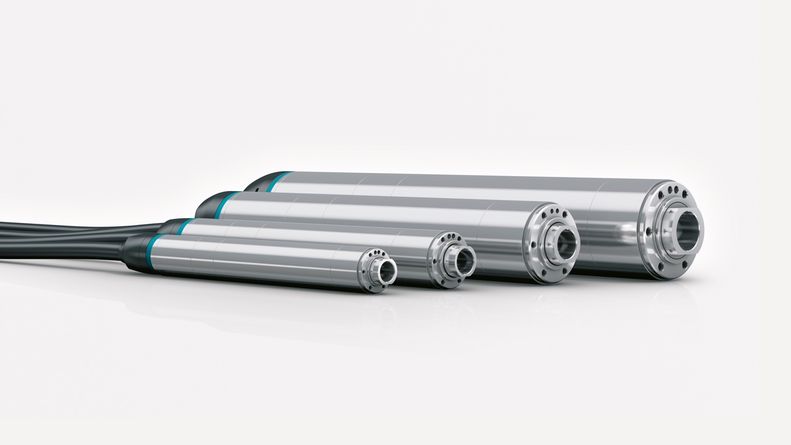

The linear actuators are available in sizes from 17 to 40 mm. Available in alternative cable configurations with radial or axial outlet, enabling space-saving and flexible integration into various installation scenarios.

Optionally, the motors can be extended with a holding brake (size 40) in Inox and Hygienic design.

![]() For a reduced project planning workload in your electrical design, the products are available in EPLAN.

For a reduced project planning workload in your electrical design, the products are available in EPLAN.

With the cyber® dynamic actuators we are a worldwide partner in the Encompass program of Rockwell Automation.

Whitepaper: Increasing machine productivity by using an Energy Harvesting multiturn encoder system

The Energy Harvesting principle is a technology that can be used to realize miniaturized, maintenance-free and energy self-sufficient multiturn encoders. Read our whitepaper to find out how the technology is applied in a multiturn encoder system, what the advantages are of using such a system and how the new technology was successfully implemented.

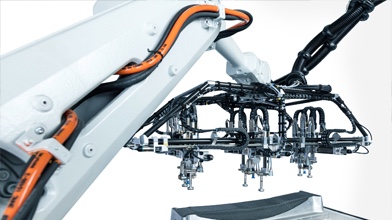

Excellent solution for complex motion tasks

Industrial grade

- Built-in absolute encoder

- Closed pushing rod with wiper

- Single-cable solution (suitable for cable carriers or torsion-capable)

- Protection rating IP54 (or higher)

Dynamics

- Maximum acceleration thanks to high overload capacity and low mass inertia

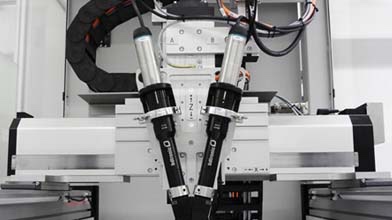

- Ideal for dynamic processes with short cycle times

Compactness

- Round design with very high torque density

- Cable solution with 90° radial outlet

- Built-in absolute encoder, anti-rotation mechanism and linear guidance

Precision

- Precise and flexible position control

- Use of high-precision ball screws

Reproducibility

- High process reliability thanks to reproducible processes

- Easy connection to your fieldbus systems

Efficiency

- Energy efficient, maintenance free drives

- Less heat dissipation

Connectivity

- Numerous real-time capable fieldbuses to connect to your fieldbus systems

- Automatic motor parameterization thanks to the electronic identification plate

Consulting and sizing

- • Individual on-site consulting

• Sizing with cymex®

• Documentation in EPLAN

Product highlights

With the linear actuators in the cyber® dynamic line, the screw is fully integrated in the actuator housing – the servo motor, spindle drive, linear guide and encoder system form a closed, highly integrated and ready-to-install unit. All sizes are equipped with an absolute encoder and feature single-cable technology suitable for use in cable carriers or torsion-resistant applications.

Furthermore, optional cable solutions are available in either radial or axial outlet configurations, enabling space-saving and flexible integration into various installation scenarios.

The small servo motors with integrated screw impress with their high power density and dynamics. Each of the four sizes has two different screw pitches, making them ideal for applications, which are either force- or speed optimized. The linear actuators additionally have a compact design, which results in much lower mass inertia than feasible, for instance, if the screw is simply attached to the servo motor.

Small servo drive system

High-dynamic servo motors in the sizes 17 - 40 mm (optionally with gearbox and ball screw drive)

Numerous fieldbus interfaces and decentral intelligence

Safe shutdown of the system in case of emergency thanks to integrated STO (Safe Torque Off) safety function according to SIL3 without loss of productivity

Space-saving installation thanks to stackability and user-friendly pin assignment

Electronic name plate enables automatic and safe parametrization of the motor

Simple installation in the machine without an additional enclosure thanks to protection class IP65

The cyber® simco® drive 2 servo drive, the cyber® dynamic line motor series and the cyber® dynamic system are a complete match in every respect.

You can choose between numerous different fieldbus interfaces for easy connection to your higher-level controller.